ABOUT US

People-oriented, leading technology, quality first, customer first

Dongying City Dayong Petroleum Additives Co.,Ltd. with independent legal personality,Established on 2 December 2005. Registered capital reached 15 million CNY.

Passed ISO9001 quality, ISO14001 environment, ISO 45001 occupational health and safety integration management system certification in 2018.

Located at South of Yongxin Road, Kenli District, Dongying, Shandong Province, China. The company is a chemical enterprise integrating research & development, production, and sales.

PRODUCTS

Look forward to working with you

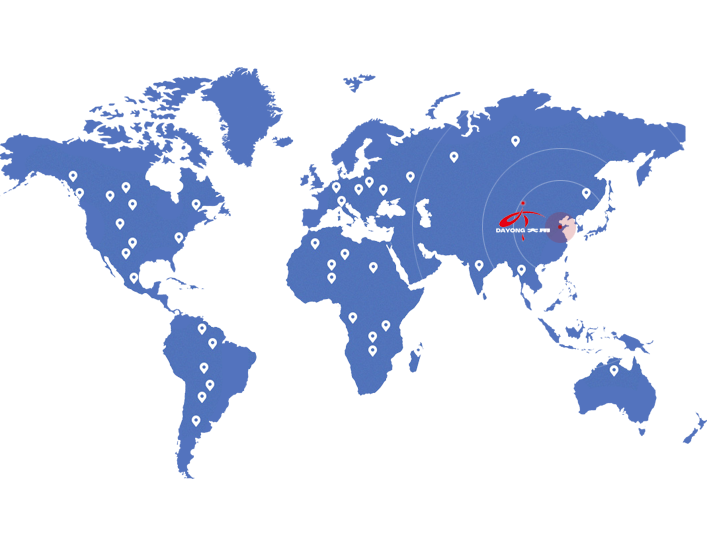

The company has modern production equipment and good, perfect experimental testing means, can carry out the detection of conventional chemical agents, so that the product inspection pass rate is maintained at more than 99%. The company has carried out a wide range of new technology promotion and application in Xinjiang, Turkmenistan, Liaohe, Shengli and other oil fields, which has been praised by customers and established a good corporate image

NEWS

Dongying City Dayong Petroleum Additives Co.,Ltd.

Add:South Yongxin Road, Kenli County, Dongying City

TEL:0546-8741007

TEL: 18654646911 Ms Yang 13780771900 Mr Su

E-mail:terry@dysyhy.com